| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 5,000,000 Meters/Month |

| Packing: | Customized |

| Delivery Date: | 10 Days | Brand Name: | Kronos |

|---|---|---|---|

| Product Name: | Thermal Break Polyamide Strips, Polyamide Struts | Material: | PA66 GF25 |

| Color: | Black | Width: | 20mm |

| Density: | 1.30±0.05 g/cm3 | Standard Length: | 6 Meters/Piece |

| Certificate: | IATF 16949:2016 | Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 | Application: | Aluminum Profiles, Thermal Break Aluminum Windows & Doors, Passive Windows |

Overview

The key component to Thermally Broken Systems are the Polyamide 66 based Glass Fiber (25%) Reinforced Pressure Extruded Insulating Strips that join two separate aluminum extrusions into one thermally broken frame.

Kronos Precision Extrusion develops and supplies high-end Glass Reinforced Polyamide Insulating Profiles for many of most energy-efficient aluminum window, door, and curtainwall products across the globe. Although most building owners and occupants may never know it, these polyamide strips are crucial to ensuring customers' aluminum products perform as intended, meeting the highest thermal performance and condensation resistance.

Used in aluminum-framed windows, doors, façades, and curtain wall systems, Kronos's High Precision Extruded Polyamide Strips optimize thermal performance helping aluminium products achieve the high-performance criteria to meet current and future design requirements, energy codes and green guidelines for both residential homes and commercial buildings. Kronos's professional experts help today's fenestration products that deliver the highest performance. We offer a wide range of standard strip designs plus numerous customer-specific designs.

Extremely Smooth Surfaces, Tighest Tolerance, Outstanding High Precision, these are the words to describe Kronos's polyamide profiles. If you buy Thermal Break Polyamide Profiles from Kronos Precision Extrusion, you'll instantly tell the difference and know just how accurate they are and how precisely they fit together with the aluminum frames.

Kronos demonstrates a high degree of excellence in engineering profiles and special tubes made of technical plastics for industrial and engineering applications.

Our polyamide profiles yield best-in-class thermal performance and exceeds not only current codes, but also exceeds every countries' stringent green building codes and standards in the market today.

Kronos's manufacturing capabilities span a broad range of products and thermoplastic polymers which makes us the perfect partner for all of your standard and tailor-made precision thermoplastic profiles extrusion needs.

Technical Specifications:

Product Name: Thermal Insulation Polyamide Profiles, Thermal Break Polyamide Strips, Thermal Barrier Polyamide Profiles, Thermal Struts, Thermal Break Polyamide Struts, Polyamide Insulating Profiles

Manufacturer: Kronos Precision Extrusion

Kronos Extrusion Model No.: 200T04

Design: Eurogroove (20°)

Main Material: Virgin Polyamide 66 + 25% Pure Glass Fiber, PA66 GF25

Processing: High Precision polyamide extrusion

Width: 20mm

Standard Length: 6 meters/piece or customized

Profile Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Strips Color: Black

Standards Carried: European Standard EN 14024:2004 & Chinese GB/T 23615.1-2017

Kronos Extrusion Certification: IATF 16949:2016

Applications: Thermally Broken Aluminum Doors & Windows

Benefits of High Precision Extruded PA66 GF25 Thermal Insulation Polyamide Profiles:

The Polyamide Strips are mechanically bonded between the aluminum frames.

The Polyamide Struts and the aluminum frames have almost identical coefficients of expansion. As a result, thermal break systems resist the thermal cycling, which occurs in actual building conditions better than any method available in today's market.

Thermal Break Polyamide Profiles will withstand heat in fenestration systems better than any other system, resulting in improved structural integrity.

The use of polyamide strut also allows for endless new product design. With this method the two separate extrusions can easily have different paint or anodize combinations, which adds significant flexibility to each individual use.

Increased Structural Strength.

Ability to make various window and door systems with the same aluminum profiles, using different sized and shaped polyamide insulating struts.

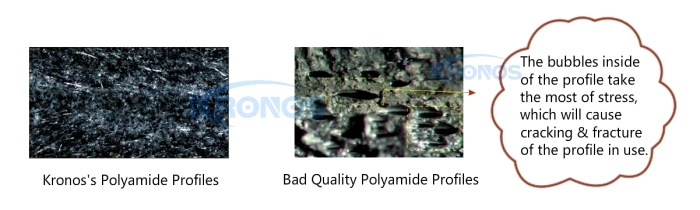

Kronos's Thermal Insulation Polyamide Profiles in Comparison with Bad Quality Polyamide Strips

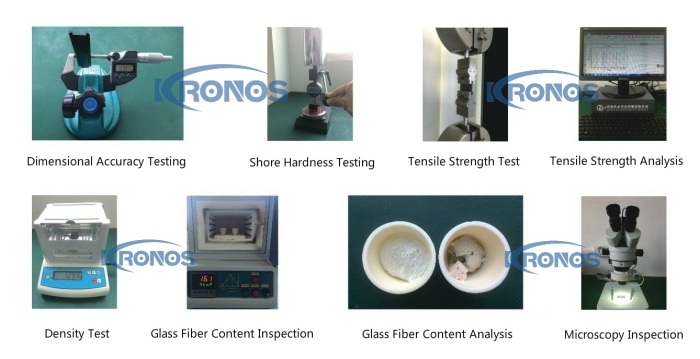

All batches of Kronos's polyamide profiles are subject to a rigorous inspection process prior to delivery.

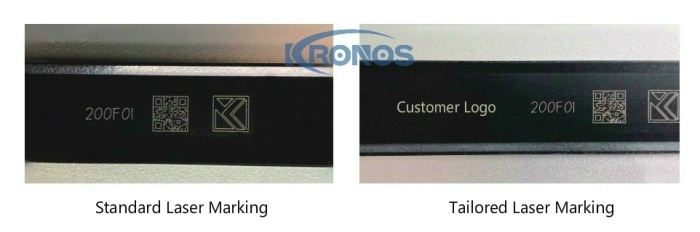

Kronos offers standard and tailored Laser Marking for easier traceability and improved quality control, adding extra value to your products and company.

Glass Fiber Reinforced PA66 GF25 Thermal Break Polyamide Strips ready for delivery

Offering nothing but the best, we pride ourselves with the use of state-of-the-art machinery to produce the top-notch quality thermal insulating polyamide strips. They are built with careful attention to detail and superb craftsmanship using innovative engineering with the leading technologies.

Our friendly and professional team is committed to ensuring you're happy not only with the product you choose, but also the service you receive from everyone at Kronos Precision Extrusion. We listen to what our customers request of us, addressing these needs, always aiming to surpass your expectations.

As you learn more about Kronos, you will discover that we are trying to achieve the same thing as you – PERFECTION.

Exchange of Know-How-The Milux Windows and the Kronos Precision Extrusion Team