| Min. Order: | 20000 Meter |

|---|---|

| Trade Term: | FOB,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Place of Origin: | Jiangsu, China (Mainland) |

| Means of Transport: | Ocean |

| Production Capacity: | 5,000,000 Meters/Month |

| Packing: | Customized |

| Delivery Date: | 10 Days | Brand Name: | Kronos |

|---|---|---|---|

| Product Name: | Thermal Break Polyamide Strips, Polyamide Struts | Material: | PA66 GF25 |

| Color: | Black | Width: | 27mm |

| Density: | 1.30±0.05 g/cm3 | Standard Length: | 6 Meters/Piece |

| Certificate: | IATF 16949:2016 | Processing: | High Precision Polyamide Extrusion |

| Standard Carried: | European Standard EN 14024:2004 & GB/T 23615.1-2017 | Application: | Aluminum Profiles, Thermally Broken Aluminum Windows & Doors |

Overview

Commonly known as Nylon, Polyamide is an inert, nontoxic material. Extruded Thermal Break Polyamide Strips have a 40-year-plus history of successful use in fenestration since their introduction in the late 1970s. The key component to Thermally Broken Systems are the Polyamide 66 based glass fiber (25%) reinforced pressure extruded insulating profiles that join two separate aluminum extrusions into one thermally broken frame.

In order to better reduce heat transfer by convection, Thermal Barrier Polyamide Bars can also be made into more complex shapes as required and used to prevent convection currents in extrusion cavities.

To ensure appropriate strength, the Polyamide Strip is Glass-Filled, with the fibers oriented in all three dimensions. As such, these strips have the capability of being used across all types of fenestration, including oversized and impact-resistant systems.

From an architectural design perspective, there are also other benefits of using high precision extruded Polyamide Struts. For example, they allow easy dual finishes on the interior and exterior of the aluminum windows and doors. Furthermore, they facilitate use of different glass packages on a building without changing the look of the fenestration.

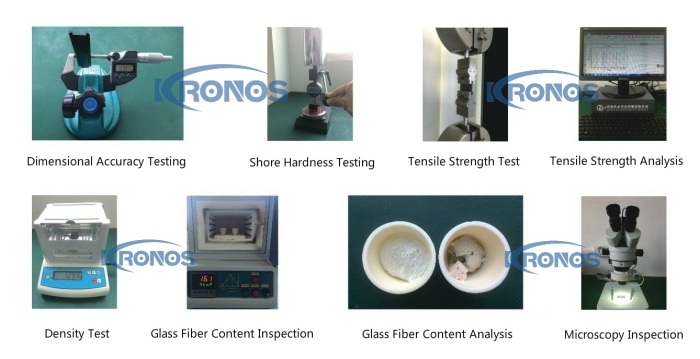

To ensure the polyamide profile system meets the required structural performance, regular Shear Testing shall be done on extrusion assemblies as a quality assurance measure during the manufacturing process.

Kronos Precision Extrusion leads the way in developing and manufacturing high-end standard and custom-made Polyamide Profiles for thermally broken aluminum windows, doors, facades, curtain wall systems, and various engineering applications.

We offer the latest in thermal performance to the fenestration industry with it's unique thermal strut separator between the aluminium profiles to achieve the ideal heat/cold insulating properties. Thermal separation in aluminium profile systems makes use of the physical advantages of plastics. Our insulating strips are tested and certified according to international regulations.

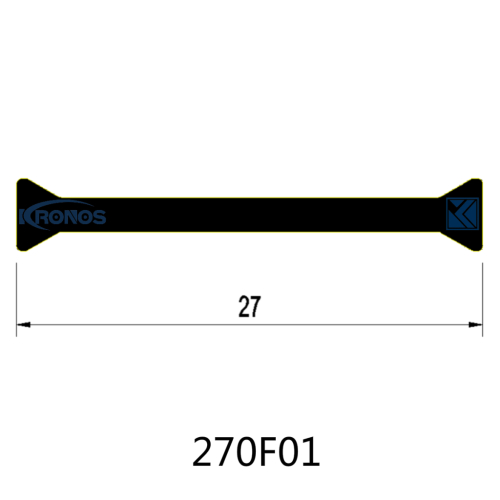

Technical Details:

Product Name: Thermal Insulation Polyamide Profiles, Thermal Break Polyamide Strips, Thermal Barrier Insulating Strips, Thermal Struts, Thermal Break Polyamide Struts

Manufacturer: Kronos Precision Extrusion

Kronos Extrusion Model No.: 270F01

Main Material: Virgin Polyamide 66 + 25% Pure Glass Fiber, PA66 GF25

Processing: High Precision Polyamide Extrusion

Width: 27mm

Standard Length: 6 meters/piece or customized

Profile Density: 1.30 ± 0.05 g/cm³

Shore Hardness: 80

Polyamide Strips Color: Black

Standards Carried: European Standard EN 14024:2004 & Chinese GB/T 23615.1-2017

Kronos Extrusion Certification: IATF 16949:2016

Applications: Thermally Broken Aluminum Doors & Windows, Passive Windows, Energy Efficient Buildings, Passive House, Sustainable Buildings etc.

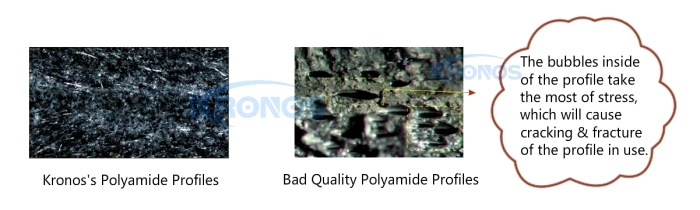

Kronos's Thermal Insulation Polyamide Strips in Comparison with Bad Quality Polyamide Profiles

All batches of Kronos's thermal insulation polyamide profiles are subject to a rigorous inspection process prior to delivery.

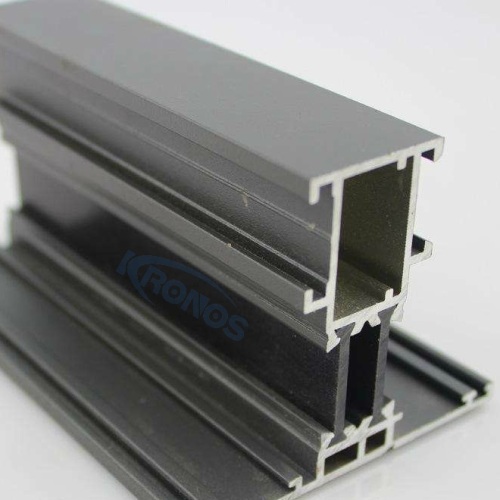

Glass Fiber Reinforced PA66 GF25 Thermal Break Polyamide Profiles ready for delivery

Offering nothing but the best, we pride ourselves with the use of state-of-the-art machinery to produce the world-class quality thermal insulating polyamide strips. They are built with careful attention to detail and superb craftsmanship using innovative engineering with the leading technologies.

Kronos has a great passion for plastic solutions. We will continue to play a very active role in contributing to the UN 2030 Agenda for Sustainable Development and Paris Agreement. Our friendly and highly-professional team is committed to ensure you're happy not only with the high precision thermal insulation polyamide profiles you choose from us, but also the service you receive from everyone at Kronos Precision Extrusion. We listen to what our customers request of us, addressing these needs, always aiming to surpass your expectations.

As you learn more about Kronos, you will discover that we are trying to achieve the same thing as you – PERFECTION.

Exchange of Know-How-The Milux Windows and the Kronos Precision Extrusion Expert Team