In the search for the lowest possible U-value, there is always room for improvement in windows, doors and facade systems. Separating the aluminum parts in windows, doors, and facade systems etc is just the beginning of the journey, but radiation and convection still present significant challenges to insulation. Optimization of the inside of the insulation zone is key to the effectiveness of the insulation. However, not so many engineers really know how to do so.

Desperately seeking optimized thermal insulation solutions? Ask the Kronos Experts!

As the Power Bills keeps soaring and a higher energy saving plan is demanded by the international communities, human beings require energy efficient products and technologies more desperately than ever. As a result, the design of Thermally-Broken aluminum doors, windows, and facade systems has been changed from simply increasing the width of the thermal insulation strips to a more complex detailed optimization of the overall heat insulation aluminum profiles. It may be a huge challenge for many experts across the globe, however this is the job that Kronos Precision Extrusion thrives upon.

Kronos Precision Extrusion is an innovative Singapore-Germany joint venture that specializes in developing and manufacturing Thermal Insulating Polyamide Profiles with Cutting-Edge High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66 (PA66 or Nylon 66) and other materials for constructional, commercial, institutional, automotive, and engineering applications.

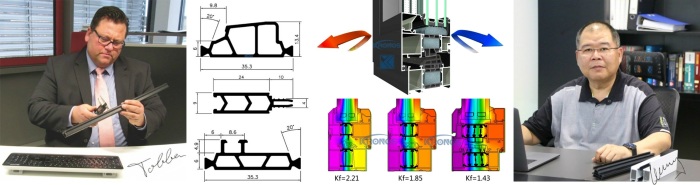

Dr.-Ing. Wilhelm H. Többen from Kronos has profound knowledge of polyamide properties, structure, and applications. Dr. Többen possesses unique technological innovation capabilities and he is also extremely-highly experienced in the production and processes of precision extrusion of polymer materials.

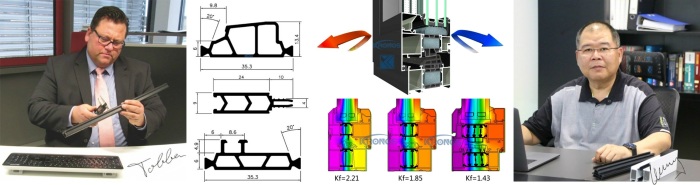

Mr. Kenny GO, General Manger of Kronos Precision Extrusion, is one of the topexperts in the plastic extrusion and thermal insulating materials, optimization, and applications. Mr. Kenny has more than 15 years of working experience in Technoform BAUTEC. When it comes to Thermally Broken windows, doors, facade systems, and Polyamide Extrusion, Mr. Kenny knows better than anyone else in the world.

Kronos Precision Extrusion Team possesses highly-professional expertise, know-how, and techniques in thermal insulation R&D and polyamide extrusion. Our proprietary design and polyamide profiles and other approaches can reduce air flow and energy loss and optimize for thermal performance without compromise. Our thermal insulation optimization make sure that we take all of your needs and concerns into account, from the production system, right the way through to structural and environmental considerations.

Kronos's Technical Services team can partner up in the R&D process in the early stage of system design, using our cutting-edge technology and know-how and super-rich experience to provide Consulting and professional Advice. We also provide K-Value calculation services. Let us work with you to find the right combination of thermal insulation solutions to reach your targets.

Desperately seeking optimized thermal insulation solutions? Ask the Kronos Experts!

As the Power Bills keeps soaring and a higher energy saving plan is demanded by the international communities, human beings require energy efficient products and technologies more desperately than ever. As a result, the design of Thermally-Broken aluminum doors, windows, and facade systems has been changed from simply increasing the width of the thermal insulation strips to a more complex detailed optimization of the overall heat insulation aluminum profiles. It may be a huge challenge for many experts across the globe, however this is the job that Kronos Precision Extrusion thrives upon.

Kronos Precision Extrusion is an innovative Singapore-Germany joint venture that specializes in developing and manufacturing Thermal Insulating Polyamide Profiles with Cutting-Edge High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded profiles from Virgin Polyamide 66 (PA66 or Nylon 66) and other materials for constructional, commercial, institutional, automotive, and engineering applications.

Dr.-Ing. Wilhelm H. Többen from Kronos has profound knowledge of polyamide properties, structure, and applications. Dr. Többen possesses unique technological innovation capabilities and he is also extremely-highly experienced in the production and processes of precision extrusion of polymer materials.

Mr. Kenny GO, General Manger of Kronos Precision Extrusion, is one of the topexperts in the plastic extrusion and thermal insulating materials, optimization, and applications. Mr. Kenny has more than 15 years of working experience in Technoform BAUTEC. When it comes to Thermally Broken windows, doors, facade systems, and Polyamide Extrusion, Mr. Kenny knows better than anyone else in the world.

Kronos Precision Extrusion Team possesses highly-professional expertise, know-how, and techniques in thermal insulation R&D and polyamide extrusion. Our proprietary design and polyamide profiles and other approaches can reduce air flow and energy loss and optimize for thermal performance without compromise. Our thermal insulation optimization make sure that we take all of your needs and concerns into account, from the production system, right the way through to structural and environmental considerations.

Kronos's Technical Services team can partner up in the R&D process in the early stage of system design, using our cutting-edge technology and know-how and super-rich experience to provide Consulting and professional Advice. We also provide K-Value calculation services. Let us work with you to find the right combination of thermal insulation solutions to reach your targets.