There are various types of Polyamide (also known as PA or Nylon). You find it in sportswear and lingerie and also in all kinds of automobile components and industrial applications. This plastic is also one of the possibilities for significantly improving the insulating capability of aluminum doors, facades, and window profiles.

Aluminum windows, doors, and facades are the standard in most modern houses and buildings. They are extremely durable, need very little maintenance and perform very well at keeping out noise. The major downside to aluminum is its Lower Thermal Insulation. The solution to this was found a few decades ago in the addition of a Thermal Barrier (also called Thermal Break). This is a low thermal conductivity element that is inserted between the inside and outside of the aluminum profiles. This insulation layer ensures a drastic reduction in the transmission of heat.

This insulating layer can take several forms, e.g. ABS, Noryl or PVC. However, none of this three material can hold a candle to the fourth option - Polyamide (also known as PA). PA is a high quality thermoplastic which is manufactured from benzene in specialized factories. Not too many years ago, the Chinese government announced that Polyamide, especially PA66 and PA6, was the sole plastic material allowed to make thermal insulation profiles for aluminum profiles.

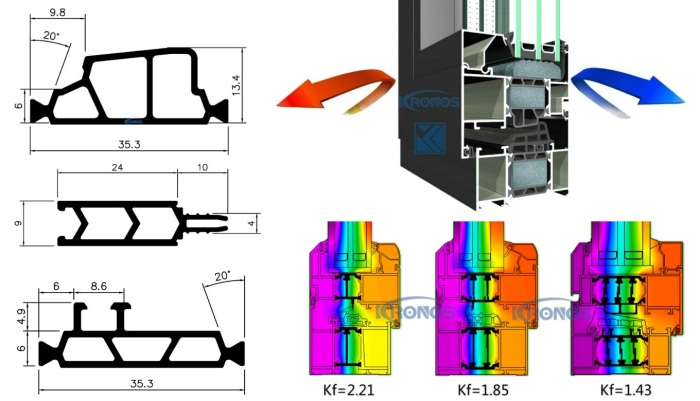

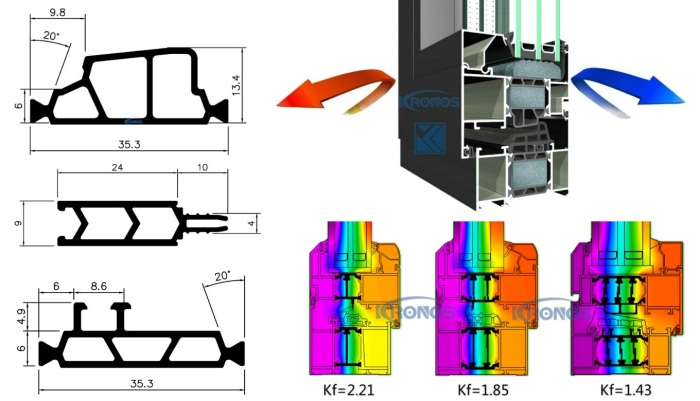

Polyamide shares a great number of advantages with aluminum (wear resistance, 100% recyclable, etc.) but also adds some more. The two aluminum extrusions are separated from each other by the Thermal Insulation Polyamide Strips. This allows the inside and outside of these types of profiles to have different colors. In addition, polyamide has a very good dimensional stability owing to its extremely small expansion coefficient. Polyamide is specifically resistant to very high and very low temperatures. The insertion of the insulating strips therefore has no effect on the structural strength and durability of your window profiles. All this ensures that thermal break profiles offer almost unlimited possibilities in terms of aesthetics and design.

Polyamide strips are usually extruded which is seemingly a simple process but actually very tricky if you want the profiles match your aluminum frames perfectly.

This insulating layer can take several forms, e.g. ABS, Noryl or PVC. However, none of this three material can hold a candle to the fourth option - Polyamide (also known as PA). PA is a high quality thermoplastic which is manufactured from benzene in specialized factories. Not too many years ago, the Chinese government announced that Polyamide, especially PA66 and PA6, was the sole plastic material allowed to make thermal insulation profiles for aluminum profiles.

Polyamide shares a great number of advantages with aluminum (wear resistance, 100% recyclable, etc.) but also adds some more. The two aluminum extrusions are separated from each other by the Thermal Insulation Polyamide Strips. This allows the inside and outside of these types of profiles to have different colors. In addition, polyamide has a very good dimensional stability owing to its extremely small expansion coefficient. Polyamide is specifically resistant to very high and very low temperatures. The insertion of the insulating strips therefore has no effect on the structural strength and durability of your window profiles. All this ensures that thermal break profiles offer almost unlimited possibilities in terms of aesthetics and design.

A last and even more important, additional advantage of polyamide is the excellent thermal insulation. While aluminum scores much less well than wood and PVC in that area, it performs at least as well in terms of Ufvalue thanks to the polyamide strips (which insulate 500 times plus better than aluminum). Thermal break aluminum profiles with polyamide strips are a logical choice. They not only contribute to your living comfort, but also to your health (condensation and mould have no chance). And last but not least, they again help prevent demands on your purse every month because of soaring energy costs.

Polyamide strips are usually extruded which is seemingly a simple process but actually very tricky if you want the profiles match your aluminum frames perfectly.