Kronos Precision Extrusion is an innovative Singapore-Germany joint venture that specializes in developing and manufacturing Thermal Insulating Polyamide Profiles with Cutting-Edge High Precision Thermoplastic Extrusion process and techniques. We offer a range of standard and custom-made extruded plastic profiles from Virgin Polyamide 66/Polyamide 6 (PA 66/PA 6 or Nylon 66/Nylon 6) and other materials for constructional, commercial, institutional, automotive, and engineering applications.

The cutting-edge insulation technique used by Kronos, connects the outer chamber and the inner chamber through pure fiberglass reinforced Polyamide Strips. These strips provide an ideal thermal break and come in various widths and shapes. When it comes to tensile, bending, twisting, and slipping strength of the monolithic thermal broken polyamide profile, Kronos truly excels.

Our highly experienced international technical team can provide professional advice and optimization solutions for the consideration of long-term application of the composite profiles, during cutting and manufacturing process, long-term stability and different application environment, personalized design of various shapes and forms of the Polyamide Strips.

Kronos Precision Extrusion thrives upon Wide and Intricate polyamide extrusions that challenge today's extrusion capabilities. If you buy Thermal Break Polyamide Profiles from Kronos Precision Extrusion, you'll instantly know just how accurate they are and how precisely they fit together with the aluminum frames.

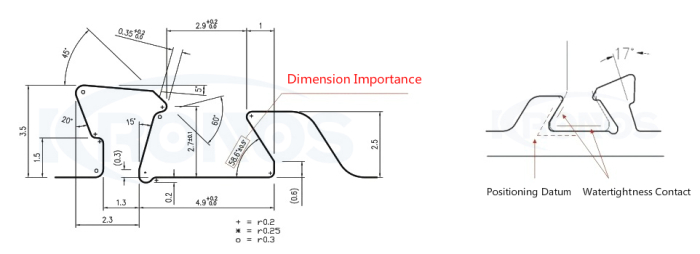

Δ The Importance of Aluminum Profiles Groove Design

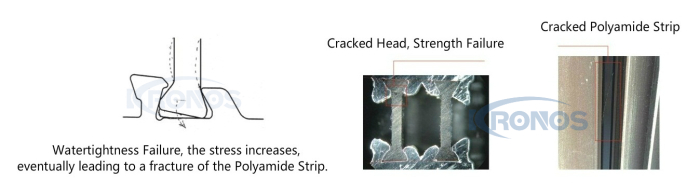

Δ Possible Consequences Due to Bad Design and Misuse

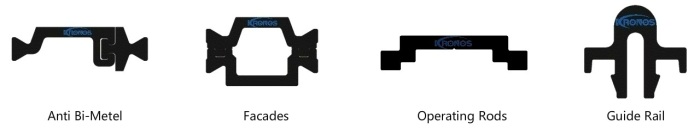

Δ Applications of Polyamide Profiles

Polyamide Profiles are widely used in Thermally-Broken Windows, Doors, Facade Systems, Operating Rods, Guide Rails, Automotive Sunroof Slide Rails, Curtain Wall Spacers, PA Edge Cover, Smooth and Silent Plastic Rail Profile for Linear Guidance, to name just a few.

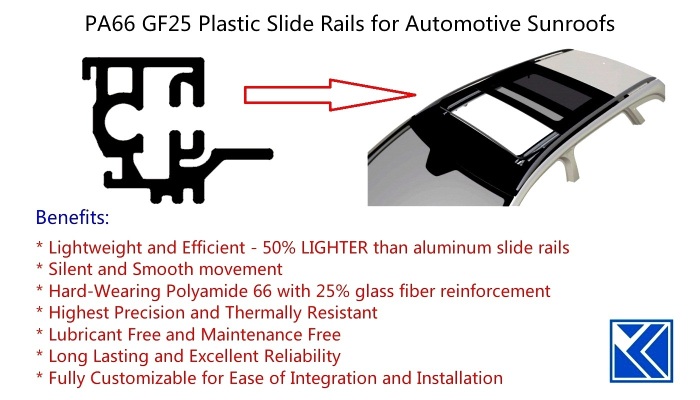

Take the automotive industry for example, many automakers are striving to make their vehicles lighter for maximum efficiency. Most of today's auto sunroofs slide rails are made of Aluminum which is heavy in weight and usually are noise during the open/close operation. Automotive sunroof manufacturuers such as Webasto, Inteva, Inalfa already use Light-Weight High-Precision Plastic Profiles to replace the heavy aluminum components for some roof modules because using lightweight, efficient plastic profiles instead of heavier metal components can help vehicle manufacturers to gain a competitive edge in many ways.

Kronos Precision Extrusion is one of the few companies which can develop and produce reinforced polyamide slide rails for the automobiles sunroofs.

Kronos Precision Extrusion is one of the few companies which can develop and produce reinforced polyamide slide rails for the automobiles sunroofs.

Benefits of high precision extruded Polyamide Slide Rails/Blind Rails/Guide Rails for Automotive Sunroofs:

- Lightweight - it's about 50% lighter than traditional aluminum slide rails

- Silent - Offer quiet movement and operation

- Smooth - Offer Lubricant-Free movement

- Long-Lasting, High Precision with Excellent Reliability & Stability

- Hard-Wearing - Virgin Polyamide 66 with 25% Fiberglass Reinforcement guarantees the strength

- Thermally Resistant

- Maintenance-Free

- Fully-Customizable - Ease of Integration and Installation for the Auto Sunroofs manufacturers