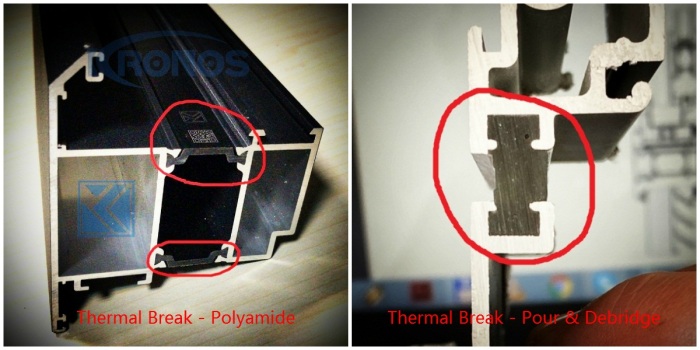

Aluminum is in most ways the perfect material for structural fenestration systems. It is incredibly strong, light, weather-proof and needs very little maintenance. However, aluminum is also a good conductor of heat. To reduce energy consumption, a Thermal Break (Thermal Barrier or Thermal Strut) of aluminum is needed. Currently, there are two principal types of thermal barriers used across the globe: Polyamide Thermal Barrier Strips and Pour & Debridge (P&D).

Polyamide Thermal Break Strips and P&D

History of P&D and Polyamide Thermal Barriers

In the 1950's, the polyurethane-based Pour & Debridge (P&D) thermal barrier system was developed in North America. This system uses a two-part polyurethane that is poured into and cured within a "dog bone" structural cavity in the finished aluminum extrusion, after the cavity surface is conditioned using either the Azo-Brader or the Lancer machinery, to limit the bridge of metal that acts as a conductor of hot or cold temperatures on the exposed surface. However, in the 1970's, it was discovered that P&D systems had a propensity to shrink, exposing many installed aluminum windows and doors to water-penetration.

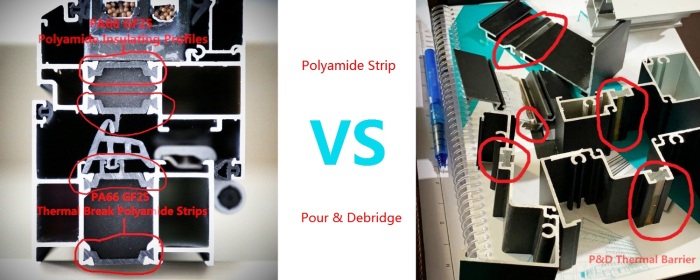

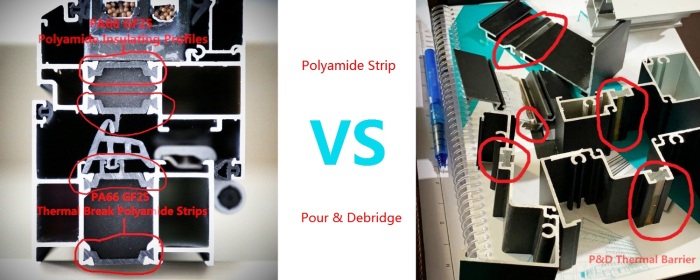

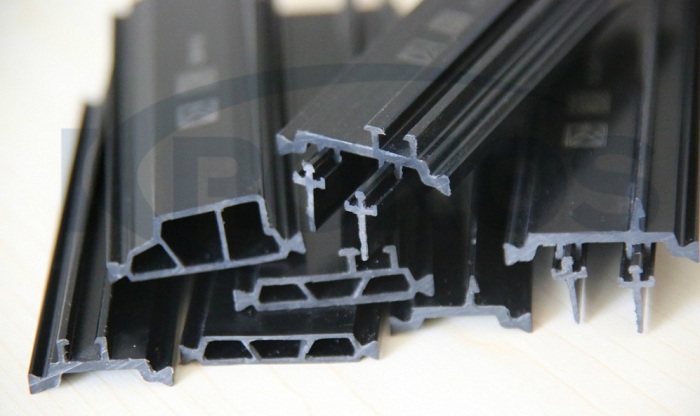

Due to the "dry-shrinkage" problem, some European manufacturers tried to look for alternatives. A unique method for extruding plastics to develop an alternate to the P&D application was developed in Germany. It was made of Polyamide 66 with 25% glass fiber reinforcement (PA66GF25). This revolutionary pressure extruded polyamide insulating strips join two separate aluminum extrusions into one thermally broken frame. Polyamide Thermal Barrier Profiles are precisely extruded through a die to achieve the desired profile shapes/geometries. The process is able to hold very tight tolerances with extremely repeatable output.

Polyamide thermal break has a higher melting point than PVC or polyurethane used in other systems; and since its coefficient of thermal expansion is very close to aluminum, the bond between it and the extrusion maintains excellent structural integrity through a wide range of temperature fluctuations.

Polyamide thermal break has a higher melting point than PVC or polyurethane used in other systems; and since its coefficient of thermal expansion is very close to aluminum, the bond between it and the extrusion maintains excellent structural integrity through a wide range of temperature fluctuations.

Polyamide insulating profile provides a true composite assembly which features Strong Structural Integrity. No thermal expansion issues due to much closer expansion coefficients between Polyamide and Aluminum.

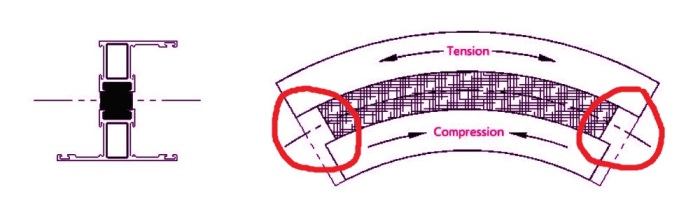

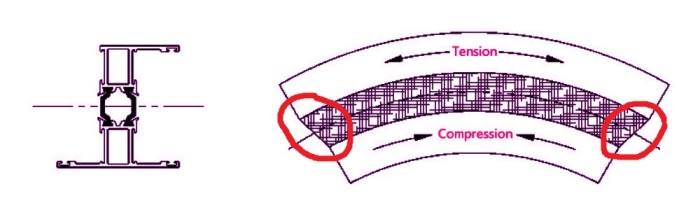

To ensure appropriate strength, the Polyamide Strip is Glass-Filled, with the fibers oriented in all three dimensions. As such, these strips have the capability of being used across all types of fenestration, including oversized and impact-resistant systems.

To ensure appropriate strength, the Polyamide Strip is Glass-Filled, with the fibers oriented in all three dimensions. As such, these strips have the capability of being used across all types of fenestration, including oversized and impact-resistant systems.

Comparison between P&D and Polyamide Thermal Barriers

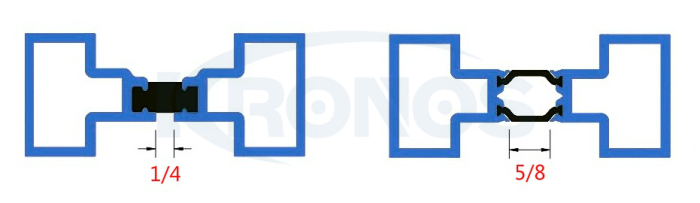

Thermal Conductivity

The thermal conductivity of aluminium alloy: 160W/M2.K

The thermal conductivity of aluminium alloy: 160W/M2.K

The thermal conductivity of polyamide profile: 0.3W/M2.K

The thermal conductivity of P&D thermal break: 0.12W/M2.K

Expansion Coefficient

Aluminum Expansion Coefficient: 2.2*10-5/K (1.22*10-5/°F)

Polyamide Expansion Coefficient: 2.5*10-5/K (1.39*10-5/°F)

Polyurethane (unfilled) Expansion Coefficient: 15*10-5/K (8.33*10-5/°F)

As we can see, polyamide profile has almost IDENTICAL expansion coefficient with aluminum alloy.

As we can see, polyamide profile has almost IDENTICAL expansion coefficient with aluminum alloy.

It is very important for the composite to remain intact over time. Hence, the choice and performance of the thermal barrier plays a key role in the structural composite assembly. The aluminum window and door systems must be able to withstand constant wind load and thermal conditions (expansion and contraction)

Thermal Break – P & D

Due to large difference in expansion coefficient, in some cases, Thermal Shrinkage will happen, leading to possible leakage and loss of composite strength!

Thermal Break – Polyamide Insulating Strips

The polyamide thermal barrier strips feature elastic Composites with Strong Shear Values, no thermal or dry shrinkage, making the thermally broken aluminum systems Strong and Safe Assemblies!

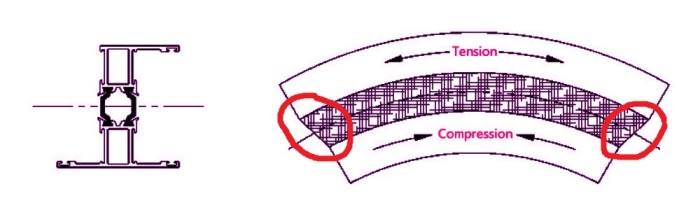

Comparing to P&D, extruded polyamide thermal barrier strip provides 2.5 times more separation when the same size is called for.

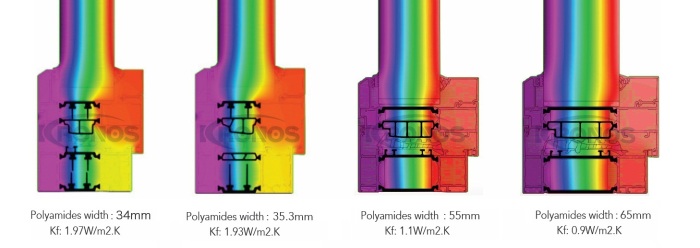

Thermal Comparison between Polyamide Strips and P&D

Polyamide insulating profiles come in various shapes/geometries and width. Both solid and hollow chamber polyamide strips are available to meet customers' specific requirements.

The wider the polyamide strips, the better heat and sound insulation.

Comparing to P&D, polyamide insulating profiles have additional benefits:

1. Polyamide Profiles will withstand heat in fenestration systems better than any other system, resulting in improved structural integrity.

2. The Polyamide Struts and the aluminum frames have almost identical coefficients of expansion. As a result, thermal break systems resist the thermal cycling, which occurs in actual building conditions better than any method available in today's market.

3. Ability to increase the separation between the inside & outside aluminum extrusions, hence improving U-values.

4. The use of polyamide strut allows for endless new product design. With this method the two separate aluminum extrusions can easily have different paint or anodize a combination, offering unparalleled design flexibility and finish options to each individual use.

5. Ability to make various window and door systems with the same aluminum profiles, by merely substituting the polyamide profile (using different sized and shaped polyamide insulating struts).

Both polyamides and P&D are accepted worldwide as the premier choices for thermal protection. Polyamide Thermal Breaks have been in use in Europe for decades. P&D is the main used system for thermal barriers in North America. Many American organizations support the use of Polyamide Thermal Barriers as one of the best methods for improving energy usage in aluminum fenestrations. It is clear that Polyamide Struts will be more and more popular in North America.

The two German thermoplastic extruders, namely Kronos Precision Extrusion and Technoform Bautec, develop and produce the best quality Polyamide Insulating Profiles with the highest precision. The American company Azon is the leader in Pour & Debridge.